Why Motors Need Rewinding

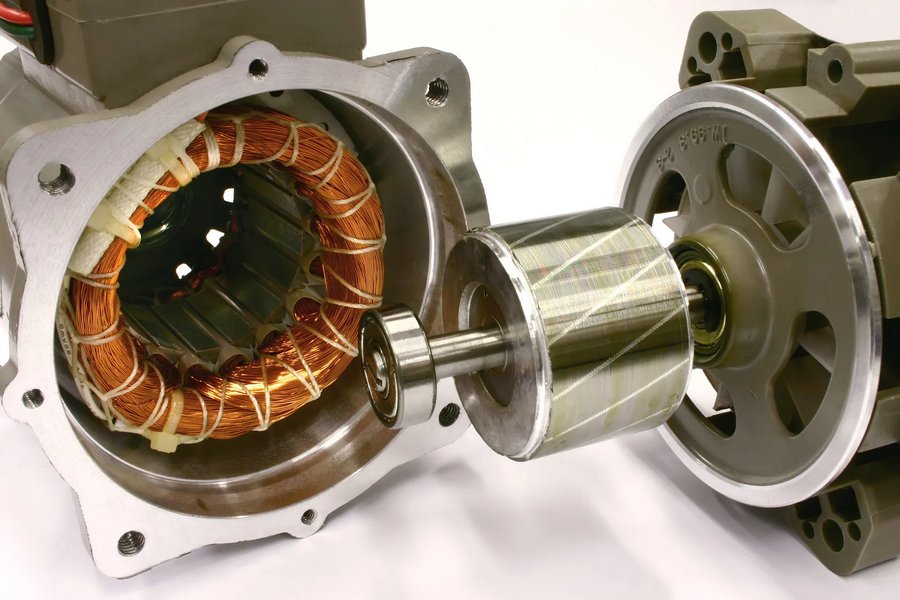

Electric motors are used in various applications in many different industries, from household appliances to large industrial machinery. Motors are built to last, but they can still wear out over time due to various factors, such as overheating, overloading, and exposure to moisture. When a DC motor rewinding begins to malfunction, it can be a costly problem for businesses, as it can cause downtime and lost productivity. In this article, we will tell you the reasons why your electric motor needs repair:

Friction

Over time, electric motors undergo wear and tear due to various factors such as vibration, heat, and friction. When this happens, the insulation on the wires may become worn or damaged, leading to short circuits or other electrical problems. Motor rewinding can replace the worn or damaged insulation, and restore the motor’s electrical performance.

Excessive Heat Generation

Electric motors generate heat when they operate, and if they get too hot, the insulation on the windings can become damaged. This can cause a short circuit or other electrical problems, and the motor may stop functioning altogether. Motor rewinding can help address this issue by replacing the damaged windings and installing new insulation that is better suited to handle the motor’s heat output.

Overloading

When motors are overloaded with too much current, they can become damaged. The windings can become overheated, which can lead to insulation breakdown and short circuits. Motor rewinding can help address this issue by installing windings that are designed to handle the motor’s power requirements without becoming overloaded.

Environmental Factors

Moisture, dust, and other environmental factors can cause damage to the motor’s windings. Moisture can cause the insulation to deteriorate, while dust can clog the motor’s cooling system, causing it to overheat. Motor rewinding can help address these issues by installing new windings with insulation that is better suited to handle the environmental conditions.

Improving Efficiency

Motor rewinding can also help improve the motor’s efficiency. When the windings are replaced, they can be rewound with better quality wire and insulation that is better suited to handle the motor’s power requirements.

Conclusion

Electric motors are essential components in various industries, and they are designed to last for many years. However, wear and tear, overheating, overloading, and exposure to environmental factors can cause them to malfunction. Motor rewinding can help address these issues by replacing the damaged windings and installing new insulation that is better suited to handle the motor’s power requirements. By performing motor rewinding at electro mechanical company businesses can save money on costly motor replacements and keep their operations running smoothly.

Soccer lover, foodie, ukulelist. Eames fan and screen printer. Let’s chat.