What is the Purpose of a Belt Sander?

Belt sanders are helpful instruments for a variety of purposes. Some are better suited to woodworking than others. They can be used in limited locations to remove burrs from a variety of materials. Continue reading as we discuss the various uses of a belt sander machine.

Disc Sander

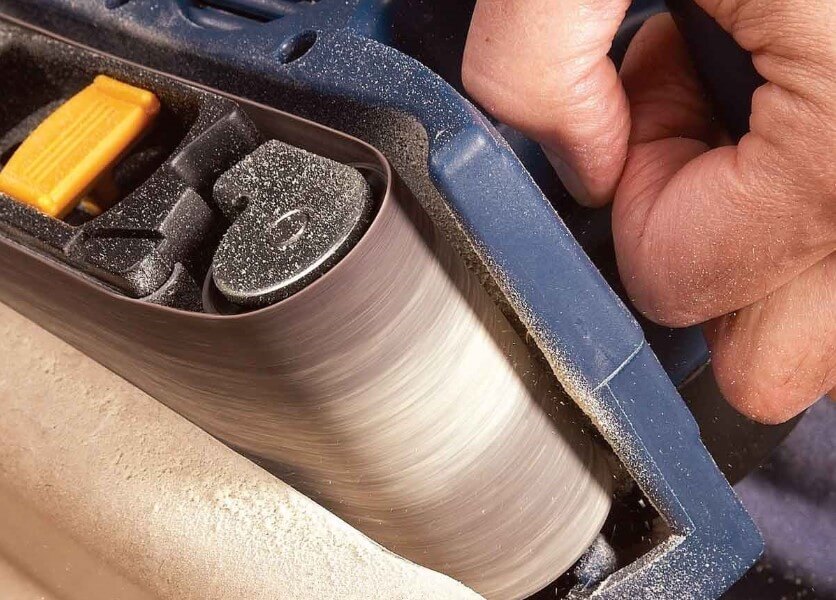

One of the most important features of a belt sander is the ability to change the abrasive belt quickly. This can save time and prevent production from shutting down. It is especially important in woodworking shops, which deal with a variety of materials. A wide belt sander should be able to swap out abrasive belts easily.

Belt Sander

Before using a belt sander machine, it’s important to understand how it works. These tools have a large amount of torque, so be careful not to get hurt while working. Also, you should keep any loose clothing off your body when using the machine, and make sure that you are using both hands when holding the tool. To begin, ease the sander onto the surface of your workpiece using a slight forward motion. Make sure that you are sanding in the direction of the grain of the wood. If you sand in a diagonal direction, you may end up with a lot of scratches and nicks.

One of the best benefits of a belt sander is its versatility. It can be used for vertical and horizontal sanding, and it can easily get into tight spaces and work with odd shapes. Another great thing about this machine is that it has a closed construction, which means that dust is not able to get into the motor. This extends the life of your machine’s motor and saves you money on maintenance. Another advantage of a belt sander is its small size, which is great for curved work.

Slack-Belt Sander

A slack-belt sander machine can be used for a variety of purposes. It is ideal for removing materials from different surfaces, including metals. Its unique design allows it to access tight spaces and work with odd shapes. Another advantage of this machine is its closed construction, which prevents dust from fouling the motor, extending its life. It also requires minimal maintenance.

Before starting a sanding job, it is important to set the belt orientation. Some belts have a favored direction, while others can be installed in either direction. If you are not sure, adjust the belt tracking by turning the trigger. Depending on the materials that you are working with, you may need to make adjustments as the belt moves.

Orbital Sander

If you are using an orbital sander machine to sand a flat surface, you must know how to use it properly. First, make sure the sandpaper is positioned correctly on the surface you are working on. Some sanders come with a hook and loop system that you can use to secure the sandpaper. You should also align the sandpaper with the dust removal holes on the sander. Lastly, test the sander’s performance on a scrap piece of material. Then, try working in a circular pattern to ensure that you get a smooth finish.

Orbital sanders have several advantages. While their high price can make them inefficient for finishing work, they are ideal for sanding large flat surfaces. They also produce a smooth finish that is free of swirl marks. Moreover, modern orbital sanders are equipped with a dust bag and ventilation system that keeps the workspace clean. Find a hardware tools supplier to get one.

Soccer lover, foodie, ukulelist. Eames fan and screen printer. Let’s chat.